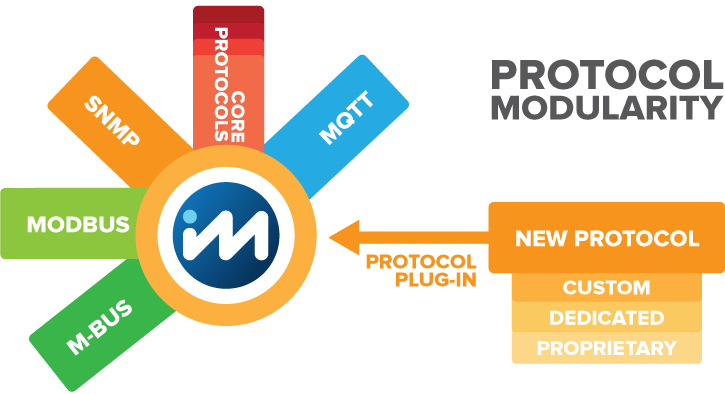

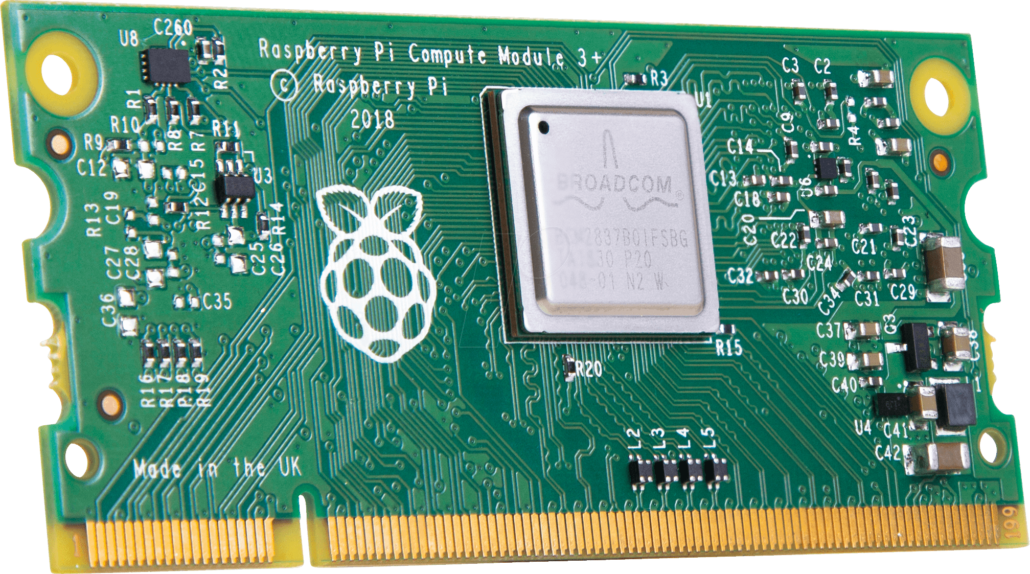

Raspberry Pi Compute Module 3+ based ModBerry industrial computer series use latest Compute Module 3+, powered by Quad-core Cortex-A53 1.2GHz processor, 1024MB LPDDR2 RAM and up to 32GB Flash eMMC. The module increase the device’s performance up to ten times, maintaining low power consumption and optimal price of the solution. Raspberry Pi based ModBerry features industrial protocol support, e.g. Modbus, M-Bus, SNMP, MQTT and the possibility to add new protocols with ease.

ModBerry remote management

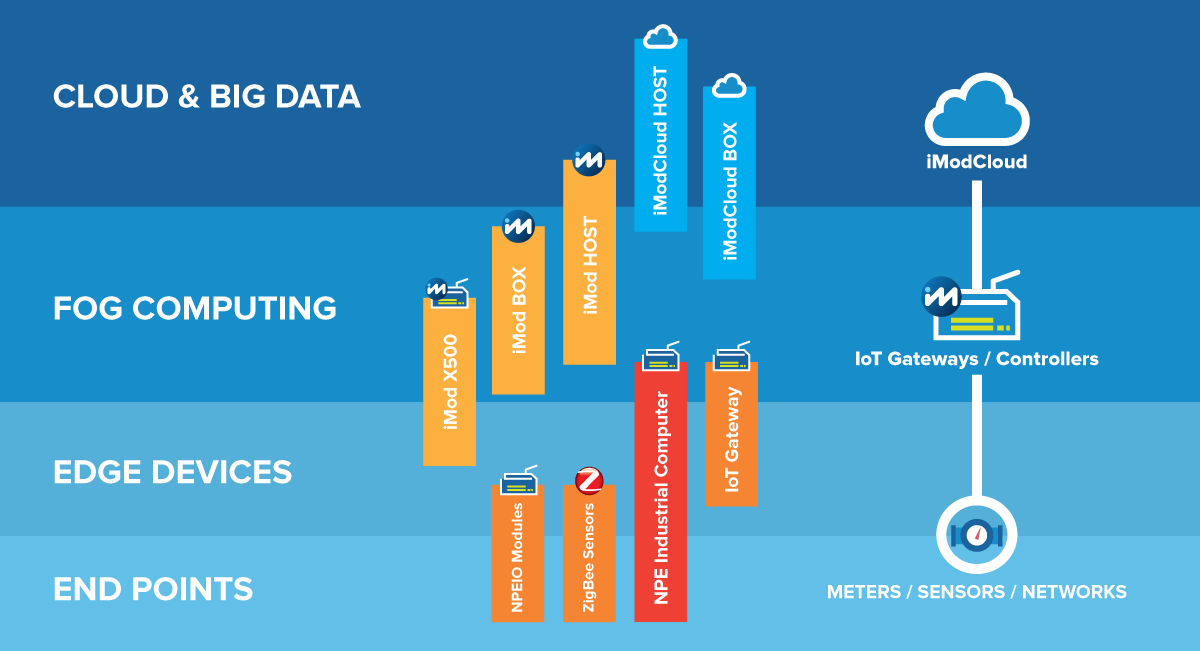

The iMod platform guarantees a quick start and full use of the ModBerry computer, without the need to write complicated software. One of the main advantages of the iMod platform is its ease of use and variety of available functionalities. Due to the available SDK, the platform can be extended with new, dedicated functionalities.

iMod can be installed directly onto ModBerry device or using external PC outside the installation (iModBOX). The third option is using dedicated hosting server to host the iMod software (iModHOST).

Another product is iModCloud software-service, which enables full control of ModBerry/iMod devices. Together they form a stand-alone solution – iModCloud Ecosystem, a combination of cloud services with web-based user interface and industrial devices, fully manageable remotely.

iModCloud can be hosted externally, using stable DELL servers to host the cloud service.(iModCloudHOST). For higher data security or depending on project features, iModCloud can be hosted internally, inside the installation (iModCloudBOX) hosted by the dedicated Mini-PC or from portable memory stick (iModCloudSTARTER).

More information Raspberry Pi based industrial device

TECHBASE provides solutions for industrial automation, telemetry, remote access and integration with IT systems. Since 2012 the company has been actively developing its competences in the market. Due to an innovative approach – based on the use of cutting-edge technologies, open standards and easy to maintain products – the company has earned the trust of Customers all over the world.

TECHBASE’s mission is to provide our Customers with tools, which will shorten and simplify the process of system implementation. With open architecture and high level of configurability, maintenance of a system is not expensive anymore.

To read more about ModBerry 500 M3 solution, download PDF datasheet: http://a2s.pl/products/ModBerry/ModBerry_500M3_EN.pdf

Read more about all ModBerry Industrial Solutions at: https://modberry.techbase.eu/

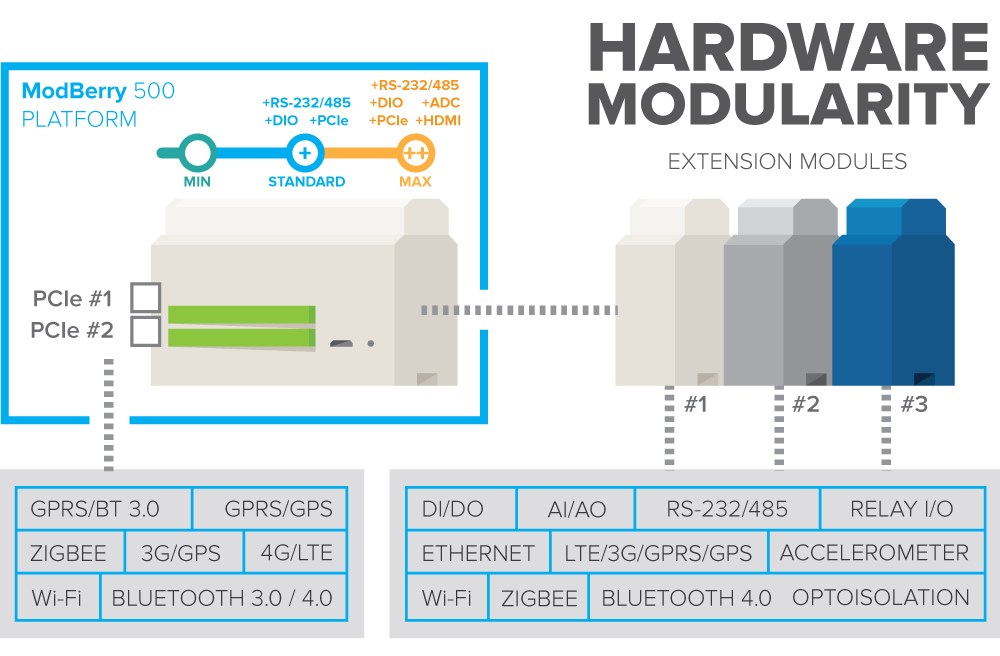

ModBerry 500 hardware modularity

The main features of ModBerry Industrial Computers series are the extension capabilities to increase input/output number, add up to 4 internal wireless communication modems and modules, support additional features such as accelerometer or opto-isolation options.

ModBerry 500 series offers wide range of industrial interfaces e.g.: digital inputs/outputs, analog inputs/outputs, relay outputs, serial RS-232/485 ports, Ethernet, 1-Wire, CAN, USB 2.0, HDMI, LTE/3G/GPRS, NarrowBand IoT/LTE, GPS, ZigBee, WiFi, Bluetooth, LoRa and many more via extension modules.